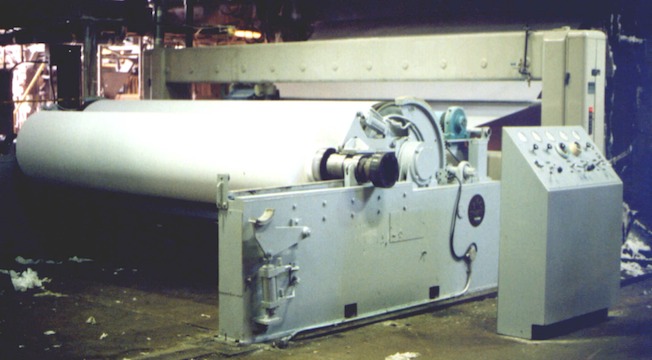

General Design

Horizontal Track style operation of winding a roll of paper on a paper machine as the paper is being produced. Reel of paper is loaded against reel drum during build up of paper roll. Primary arms and secondary arms are utilized in carrying reel spool or core shaft. Features include independent loading front to back of the reel of paper with independent controls front to back for a controlled uniformity of reels.

Description of Operation:

There are two sets of arms on our Horizontal Reel design; the primary arms and the secondary arms. The empty reel spool is placed into the primary arms and latched into place with pneumatic cylinders and bar latches. The primary arms are driven into a position where the reel spool comes into contact with the reel drum. The paper is fed through the spool / reel drum contact nip and wrapped around the reel spool with an air gun or string method. The primary arms are then driven to a horizontal position where the spool of paper is transferred to the secondary arms. Within the main reel frames are pneumatic cylinders that load the building reel of paper into the reel drum. While this reel of paper is building, an empty reel spool is placed into the primary arms ready for the next transfer. When the reel of paper has reached it’s finished size in diameter the next reel spool in the primary arms is positioned into contact with the reel drum, the sheet is broken and transferred onto the fresh reel spool. The full reel spool is removed from the secondary arms and rails and placed into an unwind station. Simultaneously, the secondary arms are positioned to receive the next reel spool from the primary arms.

Frames:

Fabricated steel construction, box section design

Reel Drum:

Cast iron drum shell with fabricated steel heads and journals, anti-friction bearings

Reel Spools:

Three reel spools are standard supply with each reel. The spools are built from heavy wall pipe or tubing, cast iron balancing type heads, and steel journals. Anti-friction bearing design with spool type housings. The journals protrude through the housings to accept reel brake couplings.

Primary and Secondary Arms:

The primary arm assemblies of our reel are mounted on the inner plates of the reel drum bearing housings and include drive gear segments, drive pinion gears, and a cross shaft. The cross shaft is driven by a gear reducer and motor with over travel limit controls and a dynamic brake. The gear segments operate between the frames and the reel drum heads. The primary arms are equipped with pneumatic cylinders and latches to secure the reel spool in the primary arms and also to apply load pressure to the reel spool during the initial build up and during the transfer into the secondary arms.

The secondary arms are mounted on heavy-duty cam follower type roller bearings that run on replaceable tracks inside the main reel frames. Air controls are provided for independent loading of the front and rear secondary arms. The arms will apply pressure only to the reel spool and do not support the weight of the roll of paper. The roll of paper is supported on the spool bearing housings that ride on frame rails on the top of the main reel frames.

Spreader Roll:

Each reel is supplied with a spreader roll for controlling the sheet of paper during the reeling process. Standard supply is a steel or rubber covered roll, crowned with a high crown for spreading action.

Doctor:

Standard supply is a doctor assembly mounted on anti-friction bearings and pneumatic cylinders for blade pressure against the reel drum.

Optional Equipment

Extended Rails:

If floor space permits, we recommend an extended rail arrangement. With an extended rail, after the finished reel of paper is done and after the sheet of paper has been broken and transferred to the empty spool in the primary arms, the secondary arms are positioned away from the reel drum under manual control and the secondary arms disappear into the main frame of the reel allowing the reel of paper to roll into a temporary storage position on the extended rails. Extended rails can be designed to accommodate as many reels of paper as space permits if so desired.

Reel Brake:

The reel brake is mounted on the main reel frame and is used to stop the finished reel of paper from rotating after the transfer has been done. The brake mechanism is fabricated from steel and standard brake lining materials, and equipped with pneumatic cylinders to apply pressure against the spool face or unwind brake coupling to cease rotation of the roll of paper.

Spool Starter:

The standard spool starter is a rubber tire driven by an electric motor. The starter assembly is in contact with the reel spool when the spool has been placed in the primary arms. The purpose of the spool starter is to bring the empty reel spool up to speed prior to contacting the reel drum. An alternative to the motor driven tire design is a traveling belt driven by the reel drum that contacts the spool while in the primary arm position.

Unwind Brake Couplings:

Female couplings (two per reel spool) are mounted on the spool journals. Male coupling mounts on the unwind brake shaft. The tooth design and shape of our couplings is such that the male and female couplings remain engaged while side shifting the spool of paper in the unwind operation

Threading System:

The threading system is a rope system design comprised of a rope sheave on the reel drum, and idler sheaves mounted on adjustable brackets. The rope system carries the rope in such a way that by feeding the tail of paper into the rope nip, the initial feeding of the paper into the reel is accomplished.

Each Horizontal Reel is engineered to meet with the customer’s needs. At the time of order placement, a representative from our company would visit the mill site to confirm specifications, space constraints, and to meet with mill personnel to discuss operations.

Sample drawings, photographs, and references to our products can be given upon request.